16 September 2025

2024-2025 Sustainability Report

Verescence is proud to unveil its 2024–2025 Sustainability Report, highlighting the tangible progress achieved through our three-pillar CSR strategy: GLASS MADE TO LAST.

From improving working conditions and empowering individuals through skills development, to cutting emissions and reducing waste, this 8th edition demonstrates how our commitments are being transformed into meaningful, measurable actions.

Key highlights from this year’s journey:

Significant drop in lost-time accidents

The lost-time accident frequency rate (TF1), a key indicator of our commitment to safety, stood at 1.85 in 2024, i.e. half that of 2023. Furthermore, our two US sites have a remarkable track record, with zero lost-time accidents for over 4 years now.

97.3% of purchases made locally

Verescence favors local suppliers wherever possible, thus reducing transport-related CO2 emissions, strengthening supply chain resilience, and supporting local economies. In 2024, more than 97% of the €231M spent on products and services went to local partners, mainly small and medium-sized enterprises (SMEs).

83% of bottles produced using post-consumer recycled glass

Incorporating external cullet from household recycled glass (PCR) into our compositions helps reduce the energy consumption required for melting and our CO2 emissions. In 2024, 10,094 tonnes of PCR cullet were used to replace natural raw materials, such as sand.

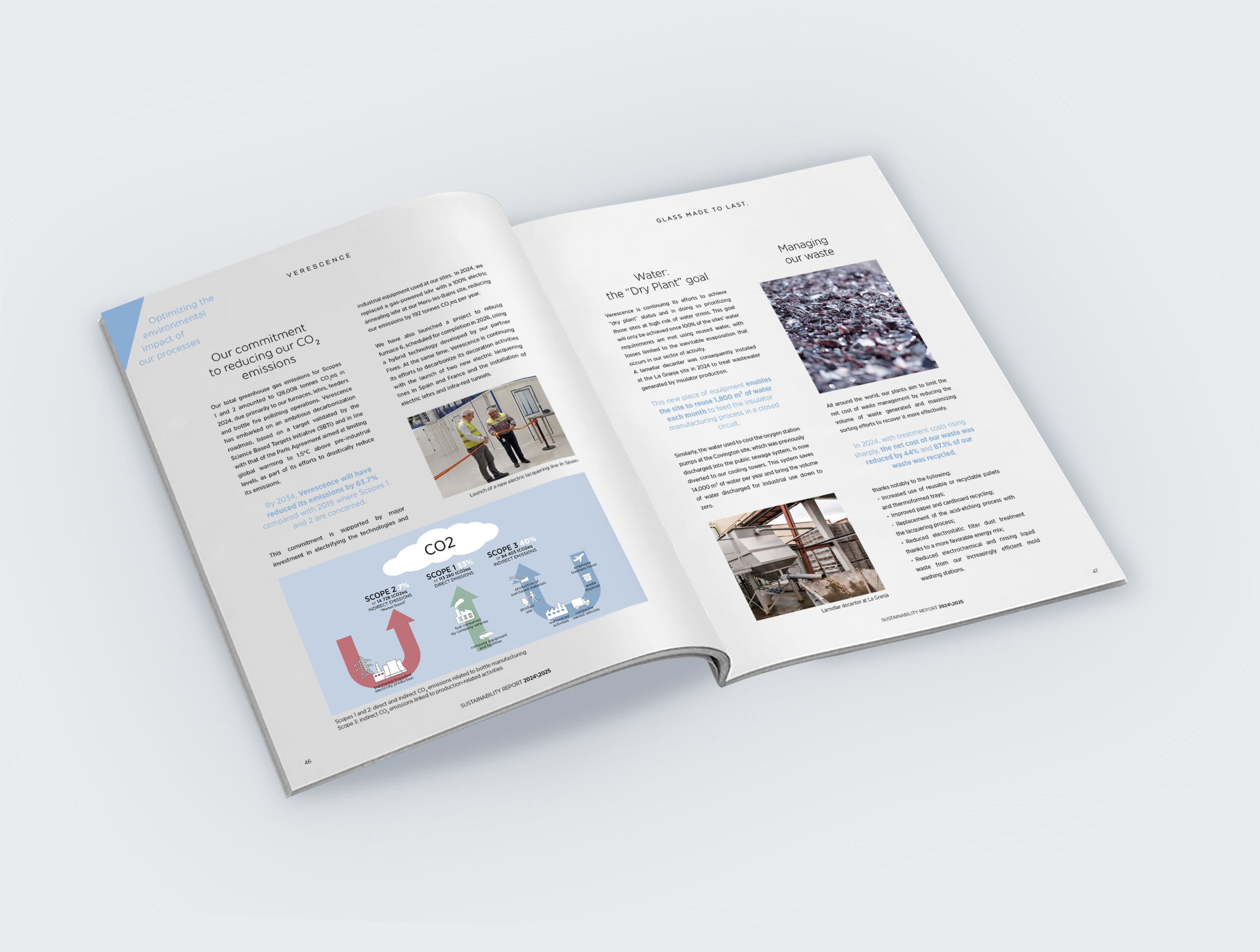

CO2 reduction target aligned with the 1.5°C trajectory

By 2034, Verescence will have reduced its emissions by 63.7% compared with 2019 (scope 1+2). This commitment is supported by major investment in electrifying the technologies and industrial equipment used at our sites. In 2024, we replaced a gas-powered lehr with a 100% electric annealing lehr at our Mers-les-Bains site, reducing our emissions by 192 tonnes CO2eq per year.

Investment in exoskeletons to prevent musculoskeletal disorders

Since 2024, some of our operators responsible for production changeovers every morning have been wearing Japet Medical’s exoskeletons to relieve their backs and prevent musculoskeletal disorders (MSDs). This innovative medical device is helping to improve working conditions in production areas and protect the health of our teams.

98% of water recycled

Verescence is advancing toward “dry plant” status by prioritizing sites facing high water stress. The goal is to meet 100% of water needs through reuse, with losses limited to evaporation. In 2024, the La Granja site installed a lamellar decanter, enabling the reuse of 1,800 m³ of water monthly in a closed-loop process. At Covington, cooling water from the oxygen station is now redirected to cooling towers, saving 14,000 m³ annually and eliminating industrial water discharge.

At the moment

View all news

The annual event recognizes the year’s best packaging designs and innovations.

Verescence Becomes a Patron of the House of Cosmetics

Verescence is among the first patrons of the future House of Cosmetics (“Maison de la Cosmétique”), set to open in Chartres in 2028, directly facing the Notre-Dame de Chart...

Verescence Recognized as Supplier Engagement Leader by CDP for the Fourth Consecutive Year

This achievement reflects the dedication of our global purchasing team in driving significant environmental changes across our supply chain.