Our expertise

MASTER GLASSMAKER SINCE 1896

More than a century has passed since the Group’s first glass manufacturing site, almost 130 years of glassmaking expertise between mouth-blown glass and today’s most advanced technologies.

Going the extra mile, pushing the boundaries, daring to reinvent ourselves… Innovation is our strength. From our design office, where we develop our models, to the advancement of our processes, from our environmental responsibility to our organizational structure, we are entrepreneurs of progress.

To give your products the prestige that reflects your brand, Verescence goes beyond expectations, offering expertise that ensures impeccable quality, elevating your brand’s premium image and turning your bottle into its most exquisite ambassador.

61

active patents and patent applications worldwide in 2023

3%

of our revenue dedicated to R&D

75

people dedicated to glass and decoration innovation

Our process

FROM RAW MATERIAL TO FINISHING TOUCH

The most beautiful bottles from prestigious brands are born from a delicate alchemy between industrial complexity and artistic creation. Glass, formed through the power of fire and the purity of sand, is a combination of natural raw materials and recycled glass. A composition subjected to the heat of a furnace at 1600°, where the magic happens and the solid becomes liquid.

1- Melting

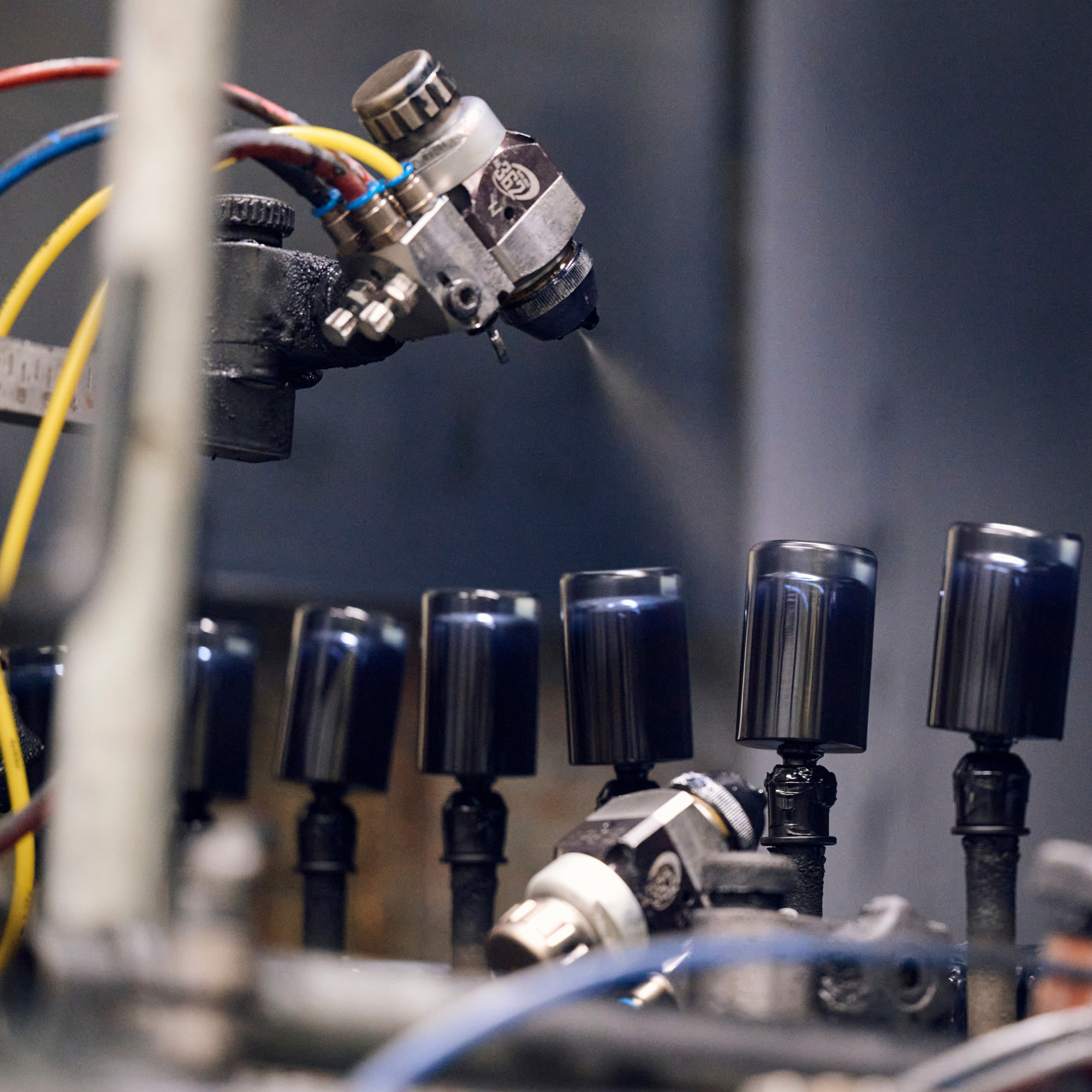

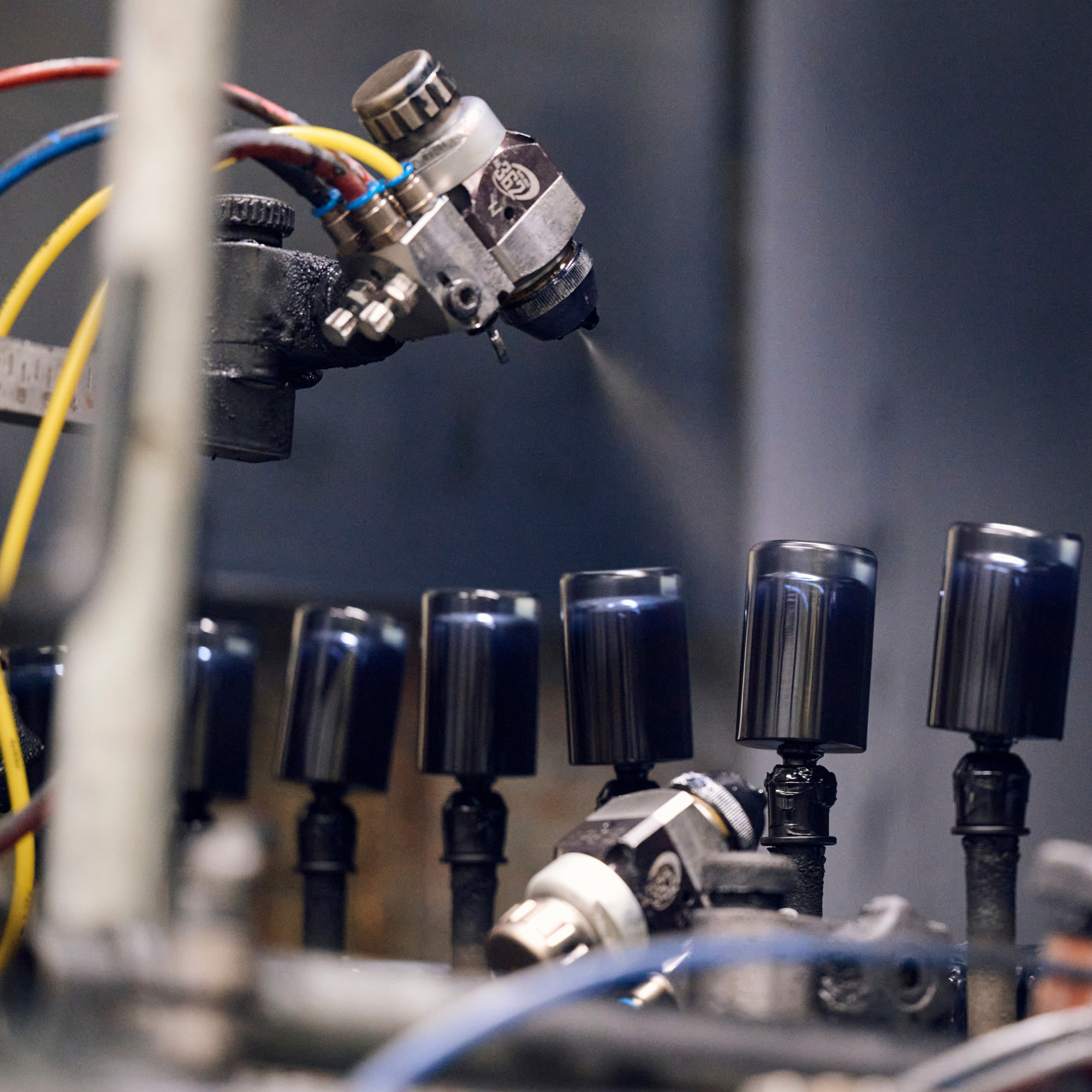

Molten glass flows through distribution channels (feeders) and is cut into drops that fall into forming machines.

2- Forming

The forming stage follows, using blow & blow, press & blow, or pure press processes. After forming, the bottle may be fire-polished to achieve a smoother surface. To enhance durability, it undergoes annealing, where it is reheated and then gradually cooled.

3- Quality Control

Before decoration, each bottle undergoes rigorous inspection to ensure the highest glass quality.

Glassmaking expertise

A FUSION OF TRADITION AND INNOVATION

To create the perfect bottle, Verescence’s expertise combines tradition and innovation. Our commitment to precision, performance, and continuous improvement drives us to refine our forming techniques and develop new glass compositions constantly.

Exclusive to Verescence

Red Glass

Melted directly in the furnace, red glass reveals its deep, unique color after annealing. This mastery allows us to create varied effects such as gradients and depth of tone.

Colored Glass

Glass coloring is achieved by adding colored enamels, or “color frits,” at the feeder’s entrance, where the molten glass flows from the furnace to the forming machine.

Patented Technology – Verescence Innovation

Infinite Glass

VERRE INFINI® 20 and VERRE INFINI® 40 contain 20% and 40% post-consumer recycled (PCR) glass, respectively. Their transparency and brilliance meet the strictest aesthetic standards of the Beauty industry.

This eco-friendly glass is 100% recyclable, reducing raw material extraction, CO2 emissions, and energy consumption.

Fine Art Engraving

Extremely fine engravings, laser-etched into molds, add texture to the glass surface. Embossed patterns create striking shadow effects, enhancing the bottle’s elegance.

Verescence Innovation

SCULPT’in

SCULPT’in revolutionizes forming by creating intricate internal shapes or personalizing the inside of jars, infusing elegance and sophistication with stunning visual effects.

Lightweight Glass

This innovative forming technique thins bottle or jar walls while maintaining mechanical resistance.

Glass Caps

An eco-friendly alternative to plastic or Surlyn, glass caps add a luxurious touch to bottles. Our glass caps are compatible with all pumps and are 100% recyclable.

Thermoluster

This technique plays with light to produce iridescent reflections on the glass surface, either subtly or intensely, alone or combined with translucent lacquering.

Our thermoluster process complies with European health and environmental standards.

THE ART OF DECORATION

A WIDE RANGE OF INNOVATIVE AND SUSTAINABLE TECHNIQUES

To elevate your creations, Verescence offers a broad selection of exclusive decoration techniques, providing differentiation for your brand.

Lacquering

Hot Stamping

Silk-screen printing

Pad Printing

COLOR'in

METAL'in

Safety Glass

Labeling & Accessory Gluing

Acid-Etching

Eco-design

MASTERING ECO-DESIGN

By integrating more recycled glass and developing new glass compositions, our ambition is to offer luxury packaging that aligns with both Beauty standards and environmental challenges.

4R&D : Reduce, Reuse, Recycle, Replace, Disrupt

Our product innovation strategy includes all our eco-friendly offerings, such as lightweight glass, refillable bottles and jars, VERRE INFINI®, and innovative glass and decoration solutions.

PCR Glass: A Major Asset in Eco-Design

Post-consumer recycled glass reduces CO2 emissions and limits natural resource extraction. Our goal is to reach 100% PCR glass production worldwide as quickly as possible, meeting increasing client demand while maintaining aesthetic quality.

MARKET TREND: the rise of refillable perfumes

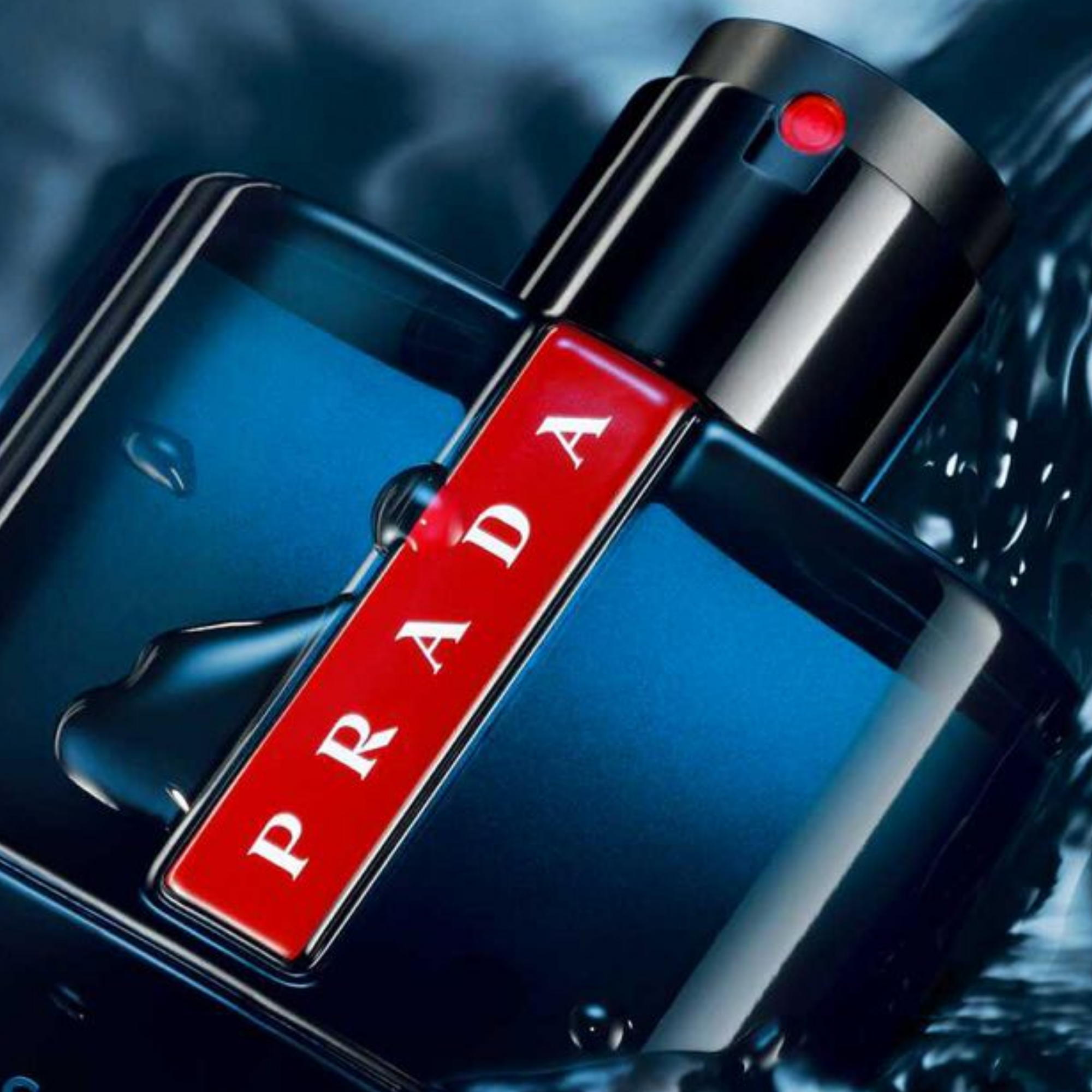

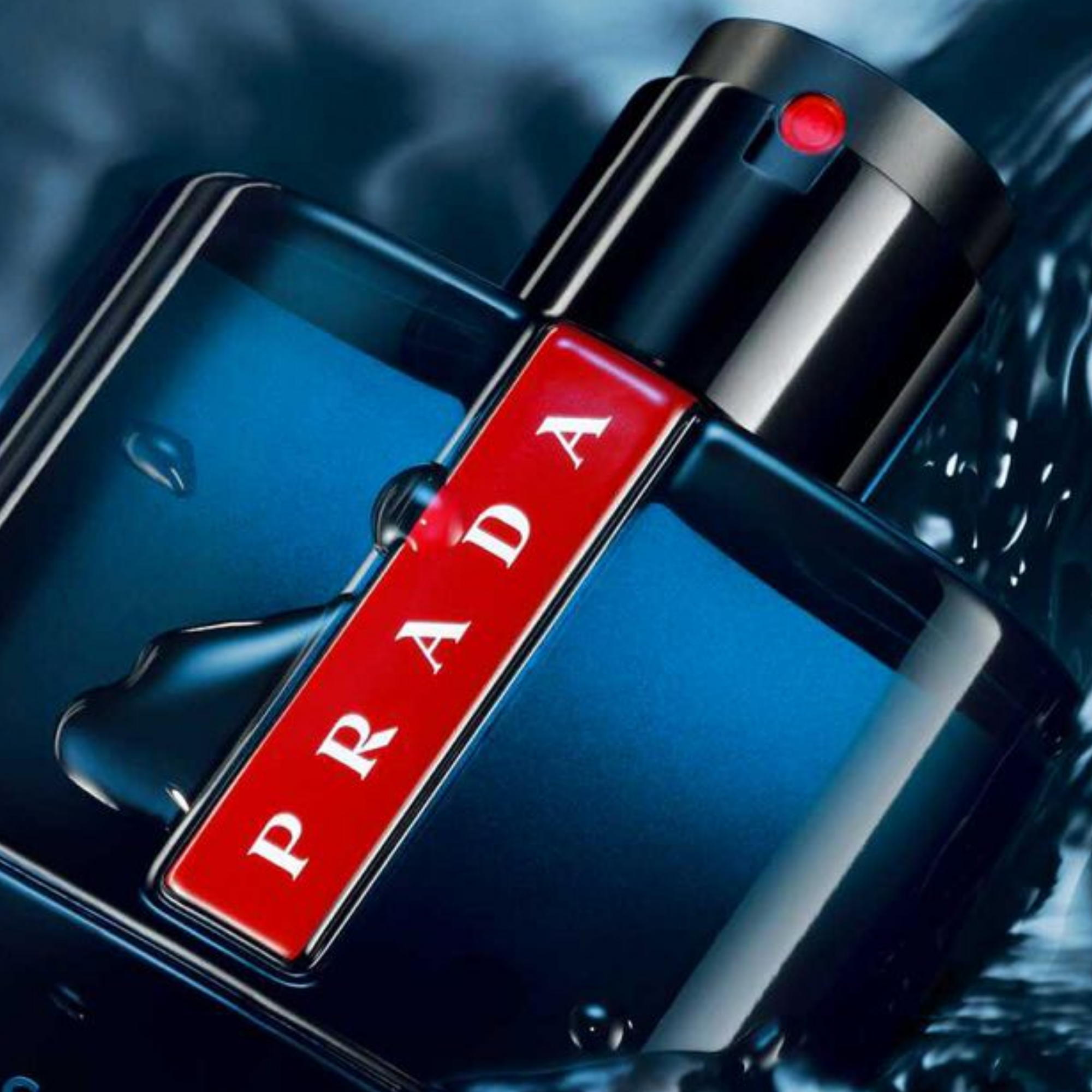

More brands are offering refillable perfumes, encouraging consumers to keep their bottles and purchase refills instead. This new sustainable practice aligns with a circular economy approach.

A concrete example of this initiative is L’Oréal’s multi-brand refill, available in 100ml and 150ml formats, developed by Verescence using lightweight glass (Glass Score A+) and 20% post-consumer recycled glass to reduce its environmental impact.

77%

of bottles produced globally in 2023 contained post-consumer recycled (PCR) glass

85%

of new fragrance launches in 2023 featured a screw neck

SUPPORTING OUR CUSTOMERS IN ECO-DESIGN

Our Glass As a Service program guides you through the eco-design of your glass bottles with a comprehensive suite of decision-making tools, including Life Cycle Analysis (LCA), a recyclability index, 3D modeling, and a glass weight reduction rating system.

RECYC’LAB

Our bottle recyclability barometer assesses the recyclability rate based on the type of glass and finishing process chosen. Developed by Verescence under real-world conditions (in-situ testing in a French sorting facility), this tool provides expert guidance from the early stages of your project.

GLASS SCORE

This new rating system, developed by Verescence, evaluates the impact of a bottle’s glass weight independently of its capacity. Since reducing glass weight is the primary lever for lowering environmental impact, Glass Score allows you to assess your product range using a universal measurement scale.

LIFE

Developed in partnership with EVEA, our Life Cycle Analysis (LCA) tool precisely measures the environmental impact of each production stage—including raw materials, manufacturing, finishing, and transportation—based on eight key indicators. This comparative tool helps you make the best choice between two design options early in the development process.

3D MODELING

Our 3D visualization tool takes into account glass distribution, selected decorations, and fragrance color to provide a highly realistic rendering before production. This reduces the need for industrial prototyping and accelerates time-to-market.

Lacquering

With an infinite color palette and multiple effects, lacquering enhances bottles, making them unique. Iridescent, gradient, opaque, soft-touch, metallic, ultra-glossy… Our lacquers come in various finishes for fully customized effects.

100% of our lacquers are water-based (solvent-free).

Hot Stamping

Hot stamping is a technique for applying metallic foil (gold, silver, bronze, etc.) to give the bottle a high-gloss, premium appearance.

Silk-screen printing

Applied in one or more passes, screen printing can be used to write, draw or even create a relief effect on the glass surface. Verescence offers environmentally friendly UV or organic inks, available in all shades.

Pad Printing

Pad printing is an ink transfer technique that uses a pad to decorate areas inaccessible to screen printing, such as the bottom of a glass bottle, the shoulders or beveled edges of a bottle, and non-flat surfaces.

COLOR'in

COLOR’in coats the inside of a bottle with a colored tint in direct contact with the fragrance. This technique enhances reflections and the glass mass, offering exceptional aesthetics—translucent, opaque, pearlescent, gradient… The customization possibilities are endless.

Patented Technology – Verescence Innovation

METAL'in

With its deep shine creating a mirror effect, METAL’in illuminates the inside of bottles. When combined with other finishing techniques, the creative potential is limitless, ensuring a truly unique bottle.

Patented Technology – Verescence Innovation

Safety Glass

Designed for capacities up to 300ml, Safety Glass is an outer coating that significantly increases impact resistance.

Verescence Innovation

Labeling & Accessory Gluing

Labels, plaques, metal pieces, plastic, or fabric elements can be automatically applied or delicately placed on specific areas of the product for a sophisticated touch.

Acid-Etching

By immersing the bottle in an acid bath, acid-etching creates a frosted effect—either full or partial—with varying levels of opacity and texture, offering a silky-smooth or rugged feel.

At the moment

View all news

Verescence will be attending LUXE PACK New York on May 7-8, 2025, at the Javits Center.

Verescence is once again featured on the prestigious CDP ‘A List’

The 2024 CDP sustainability ratings have been released, and we are proud to announce that Verescence has once again earned a place on the prestigious CDP A List!

Contact us

First, tell us who you are